A diaphragm pump (also known as a Membrane pump, Air Operated Double Diaphragm Pump (AODD) or Pneumatic Diaphragm Pump) is a positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic or Teflon diaphragm and suitable valves either side of the diaphragm (check valve, butterfly valves, flap valves, or any other form of shut-off valves) to pump a fluid.

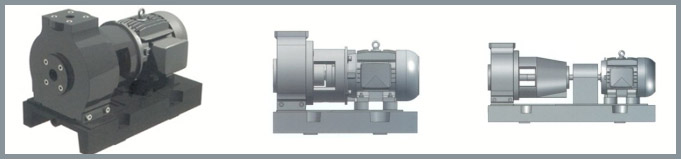

Pumps

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. In the typical case, the fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits.

Positive displacement pumps, which lift a given volume for each cycle of operation, can be divided into two main classes, reciprocating and rotary. Reciprocating pumps include piston, plunger, and diaphragm types; rotary pumps include gear, lobe, screw, vane, and cam pumps.

A metering pump moves a precise volume of liquid in a specified time period providing an accurate flow rate.[1] Delivery of fluids in precise adjustable flow rates is sometimes called metering. The term "metering pump" is based on the application or use rather than the exact kind of pump used, although a couple types of pumps are far more suitable than most other types of pumps.

A metering pump moves a precise volume of liquid in a specified time period providing an accurate flow rate.[1] Delivery of fluids in precise adjustable flow rates is sometimes called metering. The term "metering pump" is based on the application or use rather than the exact kind of pump used, although a couple types of pumps are far more suitable than most other types of pumps.

These pumps were developed to take maximum advantage from the key features of a group of synthetic thermosetting resins. The resins used are characterised by excellent resistance to chemical attack, strength and hardness comparable with many metals, and a good resistance to abrasion from fluid borne abrasives. A range of resins is used to gain optimum chemical resistance to the many fluids and chemicals encountered in industry.